VT Safety Chucks

With the VT type Safety Chuck, the replaceable inserts can be changed quickly and easily on the machine with minimum downtime. Any shape and size of insert can be chosen in many different degrees of hardness in order to offer a perfect fit of the shaft and inserts.

These versatile Chucks offer many advantages and features:

- Chucks are available for both Pedestal & Flange Mounting.

- Offer all the advantages of the Classic Chuck, but with replaceable inserts.

- Replaceable inserts minimize cost of ownership and insure long term optimal performance.

- Inserts available are:

- Square Journals – VT1 & VT2 version

- Triangular – VT6 version

- Square/Round – VT7 which is unique design for high speed and high load applications

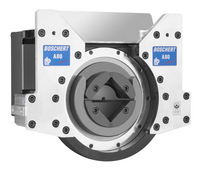

C Safety Chucks

The Boschert C Safety Chucks are the industry standard. This is a high quality product, competitively priced and suitable for lower speed applications. Safety Chucks available for both Pedestal & Flange Mounting.

The Safety Chucks offer a mechanism which self closes and ensures safe use if an operator does not close the chuck.

These versatile Chucks offer many advantages and features:

- Flange & Pedestal mounting available for all chucks

- Large range of Chucks available for a wide variety of load and speed conditions

- Bespoke backshafts available for different brake and drive requirements

Sliding Chucks

Boschert Axial Sliding Safety Chucks make it easy to locate the roll for correct alignment of the web into your machine by simply turning the handle on the rear of the driver unit and aligning axially before and during operation.

Boschert makes Axial Sliding Safety Chucks in four popular sizes capable of handling rolls has heavy as 2800kgs and torque as high as 1100Nm.

The Sidelay Safety Chuck are supplied as the VT type configuration, in either Pedestal or Flange Mounting, with all the same available features as in the standard Chucks, but with the option of 50mm or 100mm of sideways movement.

Features include:

- Pedestal Pillow Block & Flange mounting available for all chucks

- Large range of Chucks available for a wide variety of load and speed conditions

- Standard or bespoke backshafts for different brake and drive requirements

- Specialist options including Automatic Inflation,

- Available in Square Journals – VT1 & VT2, Triangular – VT6 & Square/Round – VT7

- CAD Drawings are available upon request in STEP and AutoCAD format

- Replaceable inserts minimize cost of ownership and ensure long term optimal performance

Automatic and Pneumatic series

Both Boschert Automatic Safety Chucks and Pneumatic Safety Chucks are designed to improve safety and reduce setup time in operations where Safety Chucks are required.

The Chucks fall in 2 categories: The P Series & A Series. The P Series are principally designed for new installations where Automatic Safety Chucks are to be designed into a new system, while the A Series are designed for a cost-effective backfit of Fixed Manual Safety Chucks. Remote opening and closing reduces the need for operatives, whilst excessive mechanical safety locks prevent opening while in operation or in case of electrical or pneumatic failure.

This type of Safety Chuck is designed for all manufacturing processes that require little or no operator presence and ensures maximum safety. The Safety Chucks can be supplied with Proximity sensors which will indicate:

- The loading positions

- If Chuck is open

- If Chuck is closed

Features Include:

- Pedestal Pillow Block & Flange mounting available for all chucks.

- Opens and Closes Pneumatically

- All switches and functions are safely integrated into the compact body of the Chuck.

- The chuck safely holds the shaft, transmits the torque, opens and closes automatically, and indicates if it is open or closed.

- It has an additional mechanical lock to ensure safety, even if all the electrical systems fail.

- CAD Drawings are available upon request in STEP and AutoCAD format

Multi Brake

The multi brake is the most adjustable pneumatic brake Boschert offers and can be used for all applications. It is easily adaptable to different torque and power requirements. This system includes calliper brakes which means depending on the requirements the Multi Brake can accommodate between 50Nm & 1200Nm of torque.

Safety Chuck Brakes

The Boschert ESB & DSB brakes supplied with Boschert Safety Chucks are the perfect option for unwind applications. The brakes are appropriate for all types of applications from tension control to emergency stop. Boschert offers this type of brake when using the following methods of control:

- Manual/Mechanical Control

A mechanical set screw is used to produce a fixed brake pressure. The pressure is controlled by a fine thread, this provides a fixed control and is therefore perfect where a constant tension is required.

- Pneumatic Control with Pneumatic Piston

A pneumatic piston is used to produce a changeable brake pressure. A controlled air supply is used to vary the braking torque. This type of brake has a "Slip-stick” effect which means the torque cannot be varied using an air input of below 1 bar. Nevertheless, for normal control functions this application is more than adequate.

- Pneumatic Control with Diaphragm Cylinder

There are 2 options available for pneumatic diaphragm cylinder, Membrane I & Membrane II, which are used to produce a variable brake pressure. A controlled air supply is applied to the diaphragm to produce a variable torque, producing a slipping effect. This means the brake can control torque with air inputs as low as 0.3 bar, which makes this type of brake perfect for very sensitive applications where fine torque is required.

Double disc brakes

These brakes are used on the folding bearings to achieve tension when unwinding on the winding track. Since the untangling diameter changes within the process, the braking torque must also be changed. This control can be done either manually or pneumatically.

If brakes with Boschert bearings are used, make sure that the bearings are ordered with the corresponding shaft ends.

Aluminium Cones

Aluminum Cones available for round shafts or square shafts. See Chart here. When ordering, please be sure to specify the type and size of the opening for your Aluminum Cone.

Coordinate tables for chucks

Easy Wind Tension Control

The „Plug and Play“ Tension Control

- easy installation

- constant tension over whole diameter

- ultrasonic sensor measuring the roll diameter

- simple to use

Options:

| Easy Wind: | Standard solution for one roll |

| Easy Wind Twin: | The solution for two rolls ( two sensors, one control unit ) |

| Easy Wind Sensitive: | Each brake caliper can be shut on or off |