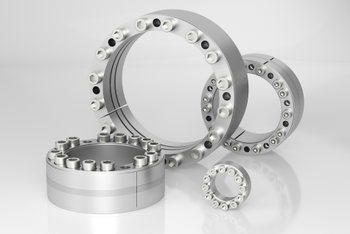

Locking Assemblies

Simple and quick assembly and disassembly, complete freedom from maintenance and wear, absolutely backlash-free power transmission: RINGFEDER® Locking Assemblies are friction-locked shaft-hub connections manufactured to the highest quality standards. They are suitable for the precise fastening of all types of hubs, e.g. toothed gears, running wheels and chain sprockets, levers, cam discs, belt and brake discs, slip-on gears, couplings or flanges, on shafts and axles. Compared to external clamping connections, e.g. shrink discs, locking assemblies are installed between shaft and hub. By tightening the clamping screws, inner and outer rings press themselves onto the contact surfaces of the components to be connected, thus creating a friction-fit press connection.

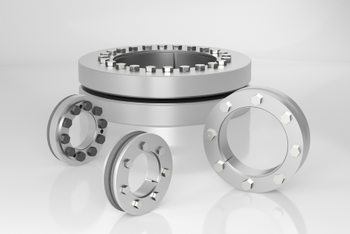

Locking Assemblies for Bending Loads

Uncompromising performance under extreme loads with specially developed RINGFEDER® Locking Assemblies for Bending Loads: One of the most challenging applications for our locking devices are belt drums which are used, e.g., in mostly large-scale conveyor systems for iron or copper ore, coal and other mineral resources. The backlash-free, friction-fit locking devices ensure highest possible operational dependability in belt drum applications and are also convincing due to their easy handling as well as complete freedom from wear and maintenance.

Locking Assemblies Stainless Steel

Proven reliability and functionality even in the toughest operating conditions: High-quality RINGFEDER® Locking Assemblies made of stainless steel are the preferred choice for all drive applications that place highest demands on the corrosion resistance of the components being used – e.g. in pump manufacturing, in the food and beverage industry and in medical technology.

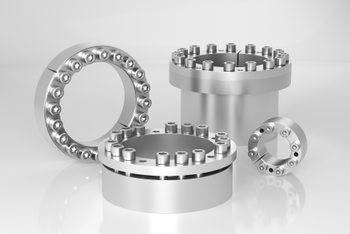

Shrink Discs

The high-quality original from the world market leader: RINGFEDER® Shrink Discs are flange-shaped, friction-locked shaft-hub connections and the more powerful and reliable alternative to conventional shrink fits, wedge, keyway or polygonal connections. In contrast to internal locking devices, e.g. locking assemblies, the pressure is applied from the outside to the hollow shaft or hub, thus creating an absolutely backlash-free, frictionally engaged connection between shaft and hub.

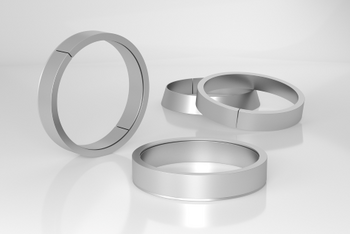

Locking Elements

RINGFEDER® Locking Elements are the most wear- and maintenance-friendly, space-saving and cost-effective design of a friction-locked shaft-hub connection. Derived initially from the proven friction spring technology, the locking elements consist of an outer and an inner taper ring, which interact to create a mechanical connection between the shaft and the component being mounted. The tensioning of the locking elements is carried out by a suitable customer design of hub and shaft.